Products

Contact Us

Address: No.5, Dongpei Road, Daitou Industrial Park, Liyang City, Jiangsu Province

Telephone: 0086-519-

Fax: 0086-519-

Mobile: +86-

Mailbox: [email protected]

Product Display

FSY glass fiber reinforced plastic liquid pump

Main material: glass steel

Flow range: 5-200m3/h

Head range: 5-60m

Length under liquid 0.35-3.5m

Power range: 1.5-37kw

Application fields: chemical industry, smelting, rare earth, pesticide, dye, medicine, papermaking, electroplating, battery separator, etc

Applicable medium: all kinds of non-oxidizing acid (hydrochloric acid, sulfuric acid, formic acid, acetic acid, butyric acid, phosphoric acid) and other salt solutions and a variety of organic solvents

Classification:

Product Description

Product overview

FSY pump is a vertical centrifugal pump under glass fiber reinforced plastic liquid. The parts in contact with the medium are made of polyvinyl butyral modified phenolic glass fiber, phenolic glass fiber reinforced plastic parts formed by high temperature molding, phenolic glass steel pipes made of connecting pipe and liquid discharge pipe by semi-dry rolling process. The assembly of impeller shaft sleeve is integrated with phenolic cement and pump shaft. The assembly of all parts under the liquid is made of phenolic cement, and there is no reliable contact with metal medium under corrosion resistance, the product has excellent properties such as light weight, high strength, no deformation, temperature resistance, corrosion resistance, etc. It can partially replace precious metals such as molybdenum-containing stainless steel, titanium and titanium alloy in anti-corrosion.

The pump adopts invasion design. The pump body is invaded into the liquid in the storage tank. The impeller is installed at the end of the rotating shaft to keep the rolling bearing away from the liquid and protect the upper parts from corrosion of the conveying medium. As the pump body is invaded into the liquid, as long as the liquid level is higher than the pump body, it can be started without filling liquid. During transportation, the leaking liquid flows back into the storage tank through the leakage hole on the central pipe, the pump has no exhaust and start-up and leakage and sealing problems, reasonable design, easy to use, because the pump body extends into the tank depth is different, the design liquid depth of 400mm to 3500mm between any choice.

The pump is widely used in chemical, petrochemical, smelting, dyes, pesticides, rare earth, leather and other industries, in the tank transport does not contain suspended solid particles, not easy to crystallize, the temperature is not higher than 100 ℃ of a variety of non-oxidizing acid (hydrochloric acid, dilute sulfuric acid, formic acid, acetic acid, butyric acid) and other corrosive medium of the ideal equipment.

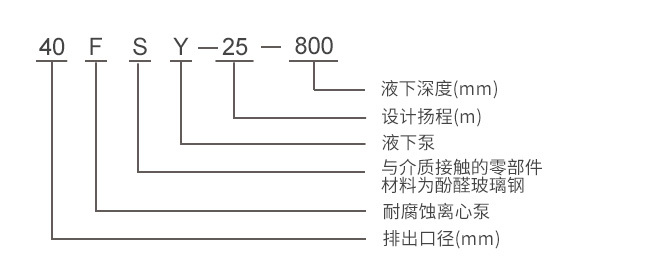

Model Description

Model and parameter

Model | Flow | Head | Speed | Power (kw) | Efficiency | Impeller diameter | Mounting dimension of base | Depth under liquid | |

| (m3 /h) | (m) | (r/min) | Shaft power | Motor power | (%) | (mm) |

| (mm) |

25FSY-20 | 5 | 18 | 2900 | 1.45 | 2.2 | 17 | 135 | Outer circle φ400 X screw hole center φ360x8 hole φ18 | 350-3500 |

9 | 15 | 2900 | 1.54 | 2.2 | 24 | 135 | |||

12 | 12 | 2900 | 1.57 | 2.2 | 25 | 135 | |||

32FSY-20 | 6 | 17 | 2900 | 1.47 | 2.2 | 19 | 135 | ||

10 | 15 | 2900 | 1.64 | 2.2 | 25 | 135 | |||

13.8 | 12 | 2900 | 1.74 | 2.2 | 26 | 135 | |||

40FSY-20 | 6.48 | 18 | 2900 | 0.99 | 2.2 | 32 | 135 | ||

15 | 15 | 2900 | 1.19 | 2.2 | 51 | 135 | |||

21 | 12 | 2900 | 1.72 | 2.2 | 40 | 135 | |||

40FSY-25 | 12 | 20 | 2900 | 2.05 | 3 | 20 | 145 | ||

23 | 17 | 2900 | 2.24 | 3 | 29 | 145 | |||

26 | 12 | 2900 | 2.56 | 3 | 22 | 145 | |||

40FSY-25 | 10 | 25 | 2900 | 1.85 | 4 | 41 | 150 | ||

20 | 20 | 2900 | 2.38 | 4 | 51 | 150 | |||

30 | 15 | 2900 | 2.63 | 4 | 52 | 150 | |||

40FSY-35 | 18 | 20 | 2900 | 1.99 | 4 | 52 | 150 | Outer circle φ540 × screw hole center φ500 × 12 holes φ18 | 350-3500 |

30 | 16 | 2900 | 2.72 | 67 | |||||

35 | 12 | 2900 | 3.17 | 69 | |||||

40FSY-35 | 7.92 | 30 | 2900 | 1.7 | 5.5 | 38 | 168 | ||

14.4 | 25 | 2900 | 2.45 | 40 | |||||

19.8 | 21 | 2900 | 3.8 | 30 | |||||

50FSY-35 | 25 | 26 | 2900 | 2.81 | 5.5 | 63 | 168 | ||

35 | 25 | 2900 | 3.35 | 71 | |||||

45 | 22 | 2900 | 3.54 | 70 | |||||

50FSY-35 | 30 | 35 | 2900 | 4.75 | 7.5 | 59 | 180 | ||

45 | 32 | 2900 | 5.42 | 71 | |||||

55 | 28 | 2900 | 6.14 | 67 | |||||

65FSY-35 | 25 | 26 | 2900 | 2.79 | 5.5 | 58 | 168 | ||

35 | 25 | 2900 | 3.31 | 66 | |||||

45 | 22 | 2900 | 3.8 | 65 | |||||

65FSY-35 | 30 | 30 | 2900 | 4.45 | 7.5 | 54 | 180 | ||

49 | 24 | 2900 | 5.51 | 57 | |||||

60 | 22 | 2900 | 6.08 | 58 | |||||

80FSY-35 | 29.6 | 35 | 2900 | 4.72 | 11 | 57 | 185 | ||

49.1 | 30 | 2900 | 5.71 | 67 | |||||

62.4 | 28 | 2900 | 6.67 | 68 | |||||

80FSY-35 | 56 | 35 | 2900 | 8.91 | 15 | 62 | 190 | ||

92.8 | 29 | 2900 | 10.54 | 72 | |||||

110 | 25 | 2900 | 11.41 | 68 | |||||

If you have special needs or working conditions, you can call the company.

Installation, use and maintenance

1. The pump should be installed vertically. The flat cover plate of the pump should be installed on the flange seat of the storage tank. Before starting operation, first toggle the coupling by hand to check whether there is any blocking phenomenon and whether the rotation is flexible.

2. Before starting the pump, as long as the liquid in the storage tank is higher than the pump body, it can be started. It is strictly prohibited to run and reverse without medium. Otherwise, the shaft lining and shaft sleeve will be damaged due to lack of liquid lubrication in the pump body. If severe vibration or abnormal sound is found, stop immediately for inspection.

3, usually pay attention to maintenance, often check whether the pump is running smoothly, there is no abnormal vibration, pay attention to the replacement of elastic block, regular supplement and replacement of bearing lubricating oil.

4. During maintenance, first remove the pump from the storage tank, remove the motor and machine base, remove the lower pump casing, remove the shaft sleeve and impeller (pay attention to the anti-corrosion layer on the pump shaft), loosen the 6 hexagonal bolts on the upper bearing seat, and then pull out the positive pump shaft and bearing parts together for maintenance.

5. For example, when replacing the bearing and pump shaft, first remove the round nut and coupling at the upper end of the pump shaft, loosen the 12 screws of the upper and lower bearing covers, and punch the bearing seat upward.

6. When reassembling after repairing and replacing wearing parts, first install the bearing seat and bearing together on the upper part of the pump shaft, seal the upper and lower bearing covers, install the coupling and tighten the round nut, correct the bending degree of the pump shaft, insert the pump shaft with bearing seat downward into the pump body, then install the bearing seat on the middle seat, and adjust the clearance between the impeller and the upper and lower pump shells, put the impeller, shaft sleeve and impeller and cap together with phenolic cement on the pump shaft. After the phenolic cement is completely solidified, install the lower pump cover. After assembly, rotate the pump shaft on the coupling by hand to see if it is normal.

Product real shot

Product Inquiry

Contact Information

Address: No.5, Dongpei Road, Daitou Industrial Park, Liyang City, Jiangsu Province

Telephone: 0086-519- / /

Fax: 0519-

Service Hotline: +86-

Mailbox: [email protected]

Mobile Website

WeChat QR Code