Products

Contact Us

Address: No.5, Dongpei Road, Daitou Industrial Park, Liyang City, Jiangsu Province

Telephone: 0086-519-

Fax: 0086-519-

Mobile: +86-

Mailbox: jszxby@liming.cc

Product Display

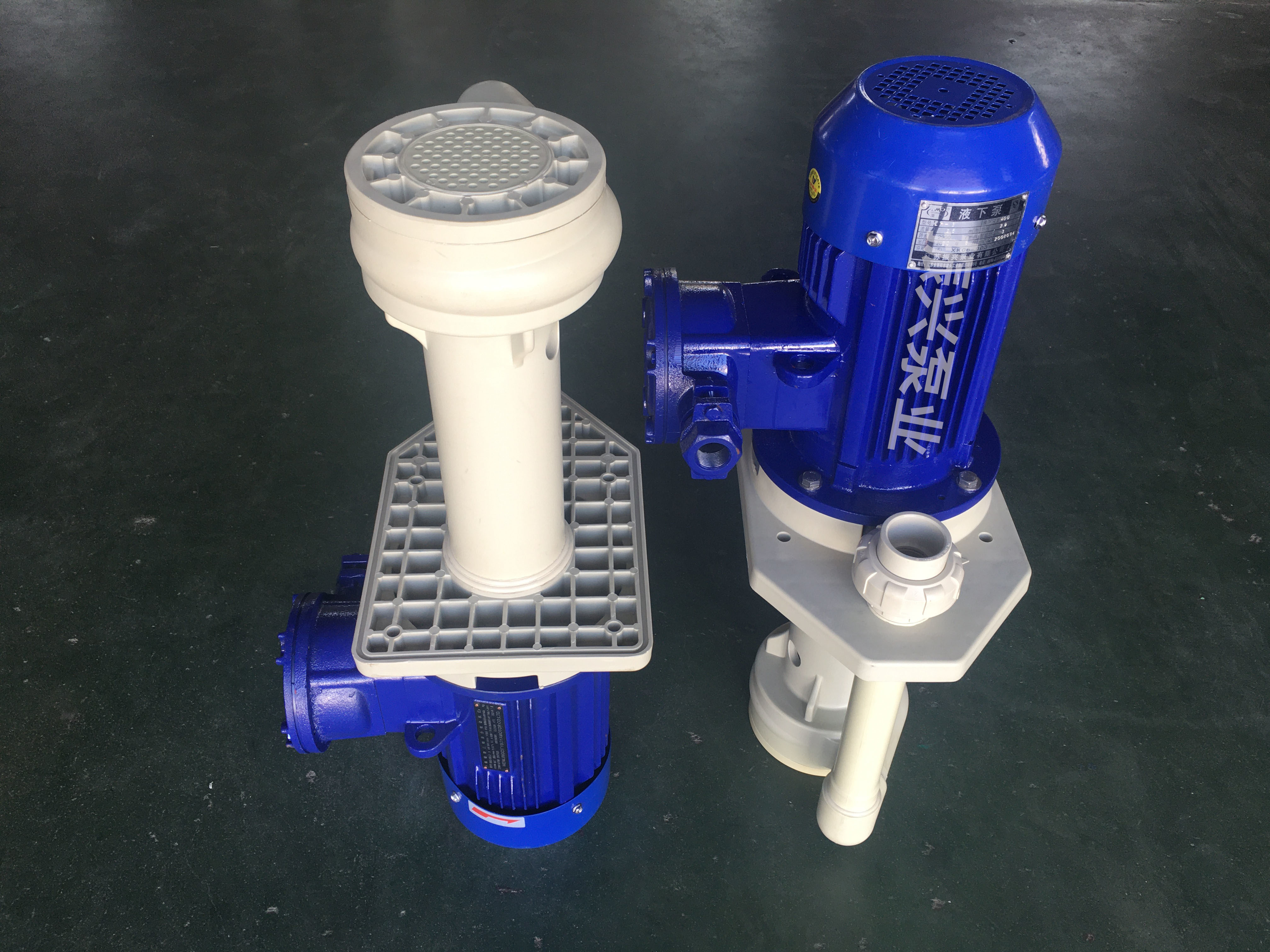

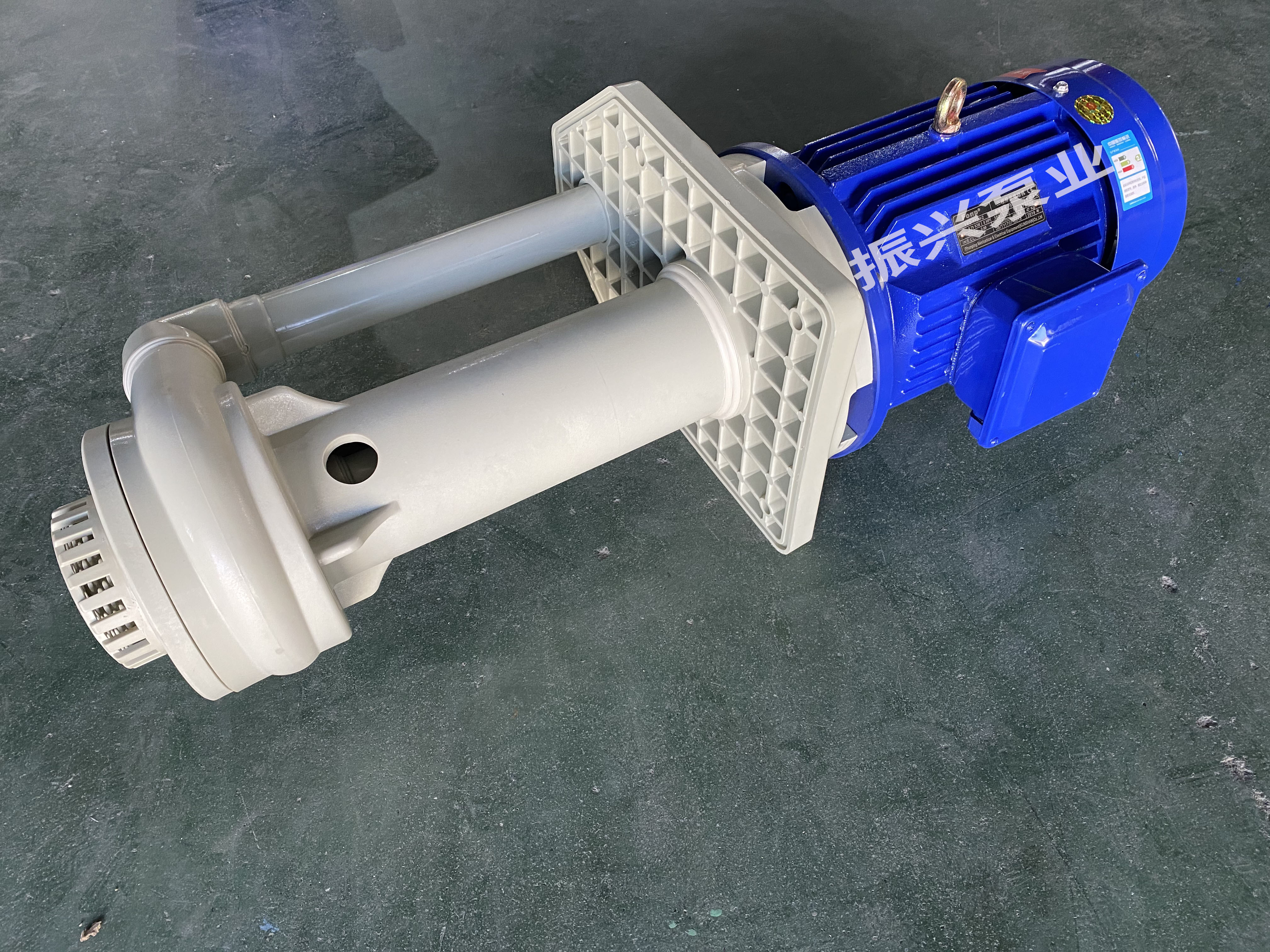

ZXCN can idle vertical acid and alkali resistant tank pump

Classification:

Product Description

Product overview

The pump body is made of PP/PVDF engineering plastic injection molding, which can resist strong acid and alkali and can run idling. The motor shaft adopts SUS304 stainless steel shaft, and the motor shaft adopts high-speed butt welding shaft process to ensure the service strength of the long shaft. The pump head assembly is completely molded, standardized, easy to disassemble and assemble, and easy to maintain. Suitable for all kinds of acid and alkali circulation, cooling, spray cleaning equipment, waste gas tower, etching, electrophoretic coating, waste water treatment, etc.

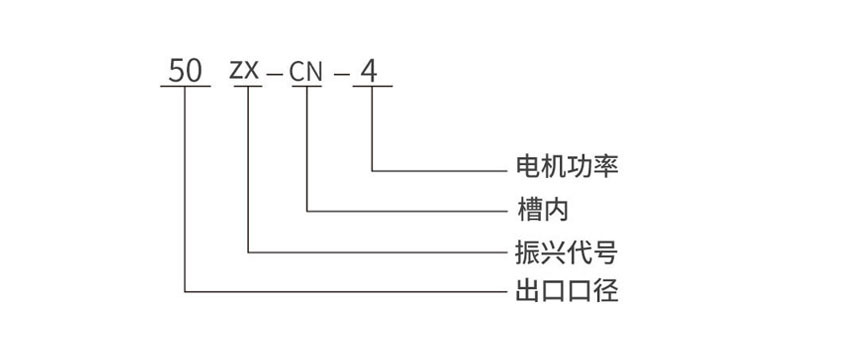

Model Description

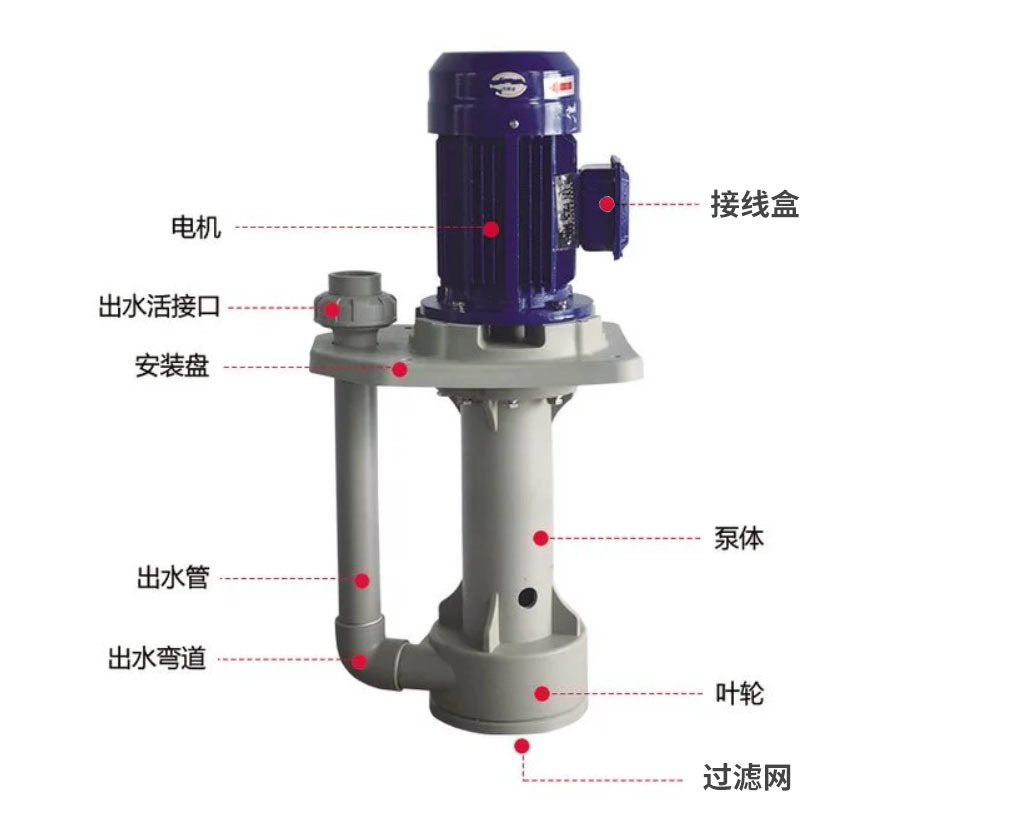

Schematic diagram of structure

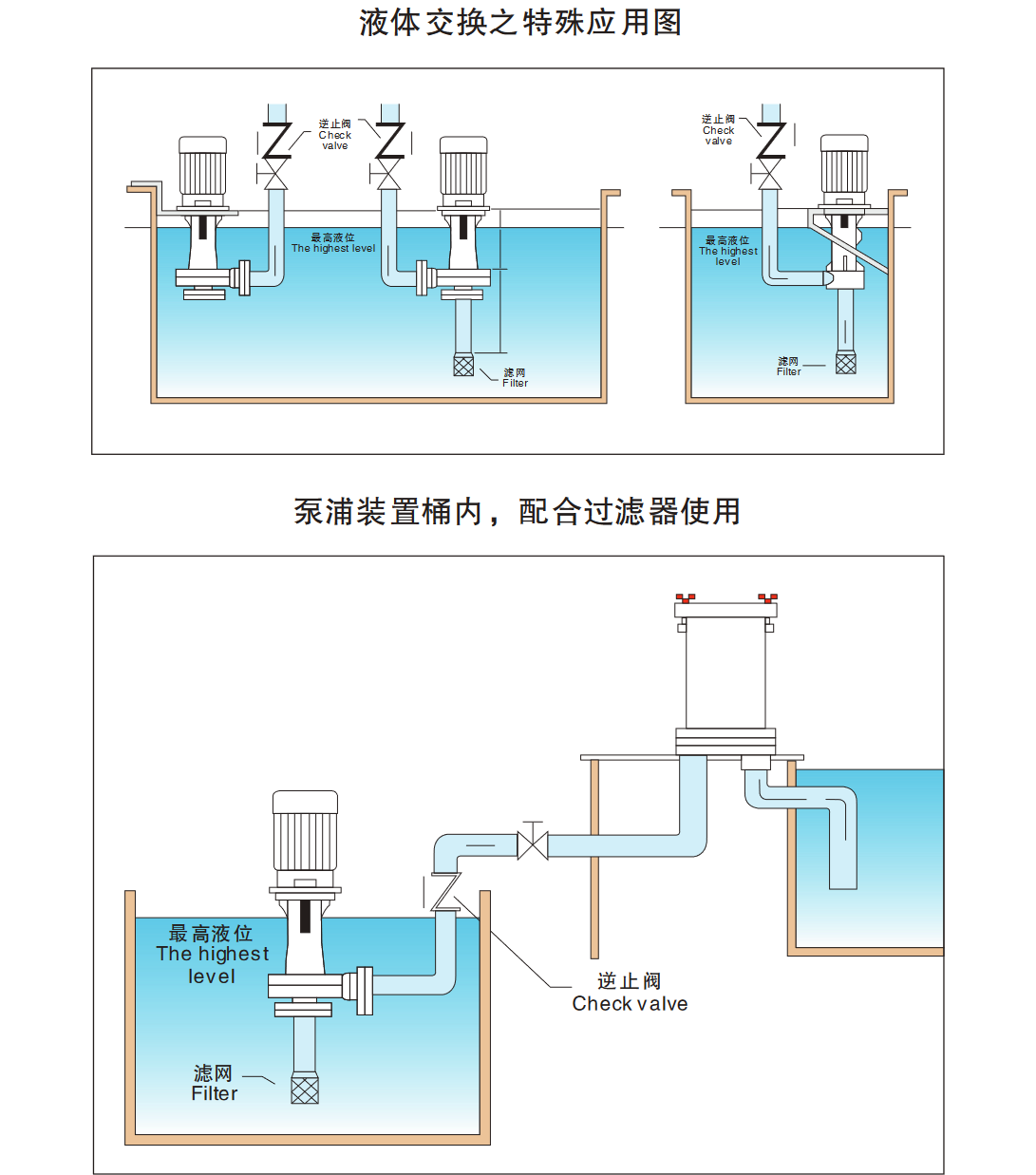

Product installation and precautions:

Installation method:

1. When installing the pump, a solid horizontal plane should be selected, and the fuselage should be kept vertical and fixed.

2. Try to avoid installing the machine outdoors. If it must be installed outdoors, it should be covered with a protective cover, and if the pump is equipped with an electronic control, it must be protected.

3, piping should first consider the use of chemical, temperature conditions and conveying head, choose different pipe material, in line with the actual requirements. For example: temperature above 60 ℃, should choose PP pipe installation.

4. When piping, it should be noted that no impurities or debris can remain in the pipe, and the pipe should be cleaned with clean water if necessary.

5. The flange joint should be lined with gaskets and locked to prevent air from being sucked into the pump.

6. When piping, attention should be paid to the fact that the pipeline should not be twisted by force. After installation, check whether the pump is twisted and deformed due to excessive force or incorrect installation.

7. After the pump is installed, confirm whether the pipeline is firm to avoid pipeline damage caused by vibration.

8. Before connecting the power cord, confirm whether the power supply used is consistent with the motor form, and connect the overcurrent protection switch.

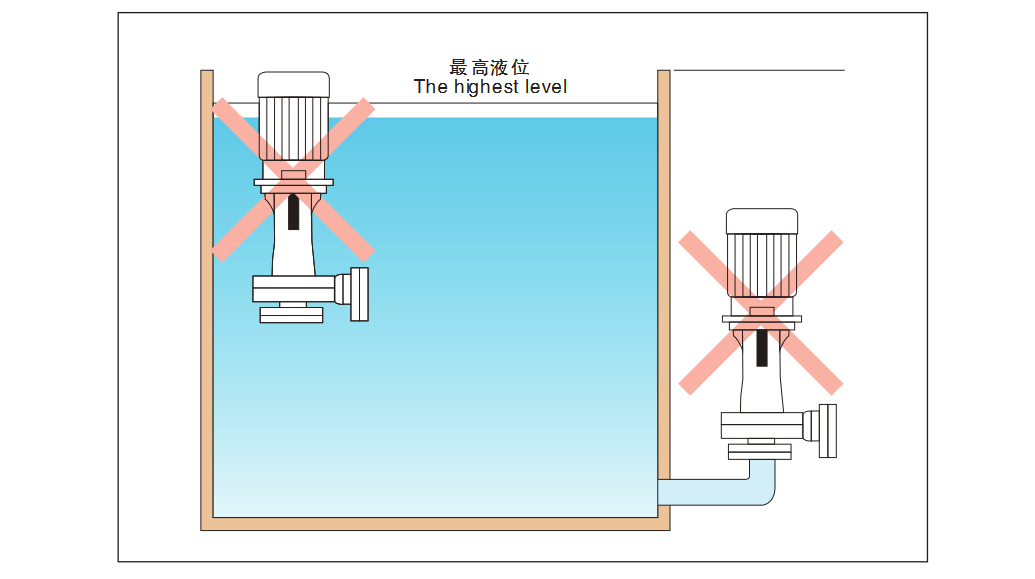

9. If the height of the outlet piping is higher than the motor or there is reverse pressure, please install a check valve at the pump outlet. The position of the device should not exceed the highest liquid level too much.

10. For safety reasons, it is best to install the inlet filter so as not to inhale debris and damage the pump.

11. The inlet connecting flange shall have the same caliber as the inlet flange, and the outlet connecting flange shall have the same caliber as the outlet flange. Warning: too tight or too loose will affect the flow performance and even

Security. Please make sure that all nuts are locked. If the nut is not locked, the liquid will leak out. If the lock is too tight, it will fall off and be damaged. Please be familiar with the installation method of this machine and equipment.

line installation.

12. The use voltage of the pump motor can refer to the motor nameplate. The circuit connection diagram can be found on the motor connection box.

Warning: incorrect use

Precautions for use:

1, the use of the pump, do not arbitrarily change the chemical nature of the transport, because of different chemical mixing will produce a variety of different chemical changes, and even chemical reactions produce high heat, damage to the pump body. Please consult professionals for chemical coordination issues.

There are many chemicals, which will cause great harm to the human body, and personnel should try to avoid dangerous areas.

3. Before starting the power supply, check the correct position of the pipeline and valve, then start the power supply, and check whether the liquid is normal at any time.

Model and parameter

|

Model |

Maximum output |

Motor power (kw) |

Rotation speed (r/min) |

Diameter of inlet and outlet (mm) |

Voltage |

||

|

Flow (m3 /h) |

Head (m) |

Imports |

Export |

(V) |

|||

|

40ZXCN-0.75 |

15 |

12 |

0.75 |

2900 |

50 |

40 |

380 |

|

40ZXCN-1.5 |

20 |

15 |

1.5 |

2900 |

50 |

40 |

380 |

|

40ZXCN-2.2 |

25 |

18 |

2.2 |

2900 |

50 |

40 |

380 |

|

50ZXCN-3 |

35 |

20 |

3 |

2900 |

65 |

50 |

380 |

|

50ZXCN-4 |

40 |

24 |

4 |

2900 |

65 |

50 |

380 |

|

65ZXCN-5.5 |

50 |

26 |

5.5 |

2900 |

80 |

65 |

380 |

|

65ZXCN-7.5 |

55 |

28 |

7.5 |

2900 |

80 |

65 |

380 |

|

100ZXCN-11 |

100 |

28 |

11 |

2900 |

100 |

100 |

380 |

|

100ZXCN-15 |

120 |

35 |

15 |

2900 |

100 |

100 |

380 |

|

100ZXCN-18.5 |

140 |

35 |

18.5 |

2900 |

100 |

100 |

380 |

|

125ZXCN-22 |

180 |

35 |

22 |

2900 |

125 |

125 |

380 |

|

125ZXCN-30 |

200 |

40 |

30 |

2900 |

125 |

125 |

380 |

Product real shot

Product Inquiry

Contact Information

Address: No.5, Dongpei Road, Daitou Industrial Park, Liyang City, Jiangsu Province

Telephone: 0086-519-

/

/

Fax: 0519-

Service Hotline: +86-

Mailbox: jszxby@liming.cc

Mobile Website

WeChat QR Code